1

/

из

9

ZONESUN

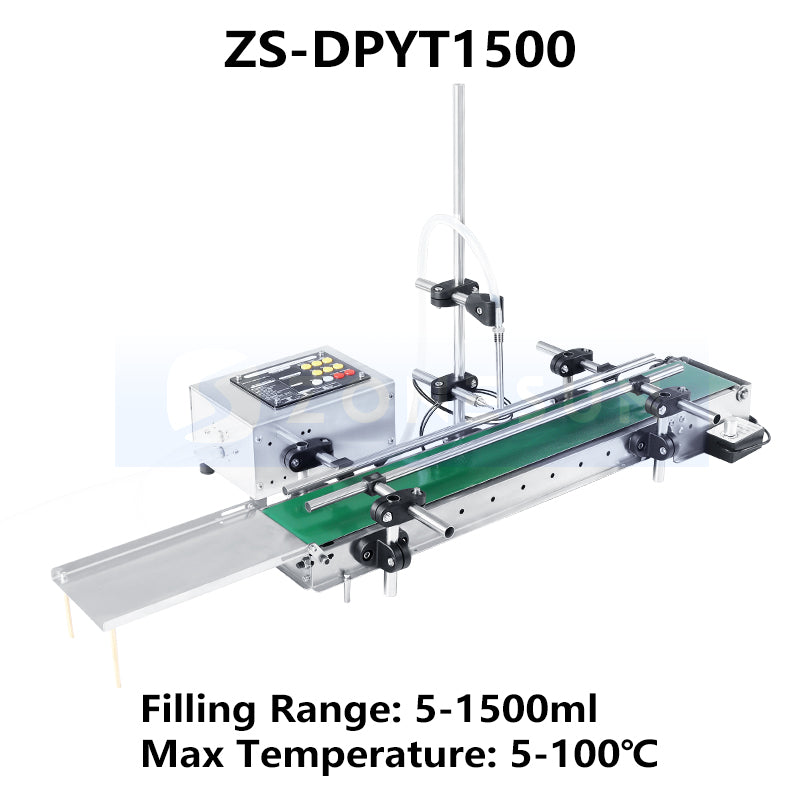

ZONESUN ZS-DPYT1500 Single Head Heat Resistant Liquid Filling Machine

ZONESUN ZS-DPYT1500 Single Head Heat Resistant Liquid Filling Machine

Обычная цена

$145.00 USD

Обычная цена

$250.00 USD

Цена со скидкой

$145.00 USD

Цена за единицу

/

за

Стоимость доставки рассчитывается при оформлении заказа.

Не удалось загрузить сведения о доступности самовывоза

Description

The ZONESUN ZS-DPYT1500 is a compact, high-precision automatic filling machine designed for low-viscosity, particle-free liquids such as water, juice, toner, and sauces. Equipped with a diaphragm pump and microcomputer control system, it offers precise timing (up to 0.1s), adjustable speed, and anti-drip functionality to keep the conveyor clean. Its intelligent sensor ensures efficient filling, while the heat-resistant design allows liquids up to 100°C. Ideal for small-scale production, the machine supports bottles up to 3L and includes removable inlet/outlet tubes for easy maintenance.

Parameter:

Machine pump:Diaphragm Pump

Voltage: 220V/110V 50-60Hz

Power: 60W

Max filling volume: 3L

Bottle height: ≤30cm

Bottle diameter:≤8.1cm

Power supply device input voltage: 100-240V

Machine input voltage: 12V 5A DC power supply

Filling time: 0-999s

Filling speed: 0-99

Filling accuracy: ±1%

Intelligent sensing distance: ≤1cm

Anti-dripping Function: Available

Notice:

1. The load that conveyor can bear must be within 3kg.

2. It is better that the distance between electric eye and bottle is within 1cm.

3.With heat resistance function, can fill liquid that is about 100℃.

4.The inlet and outlet tube can be removed and replaced.

5.Microcomputer control system, the highest timing accuracy reaches 0.1 second.

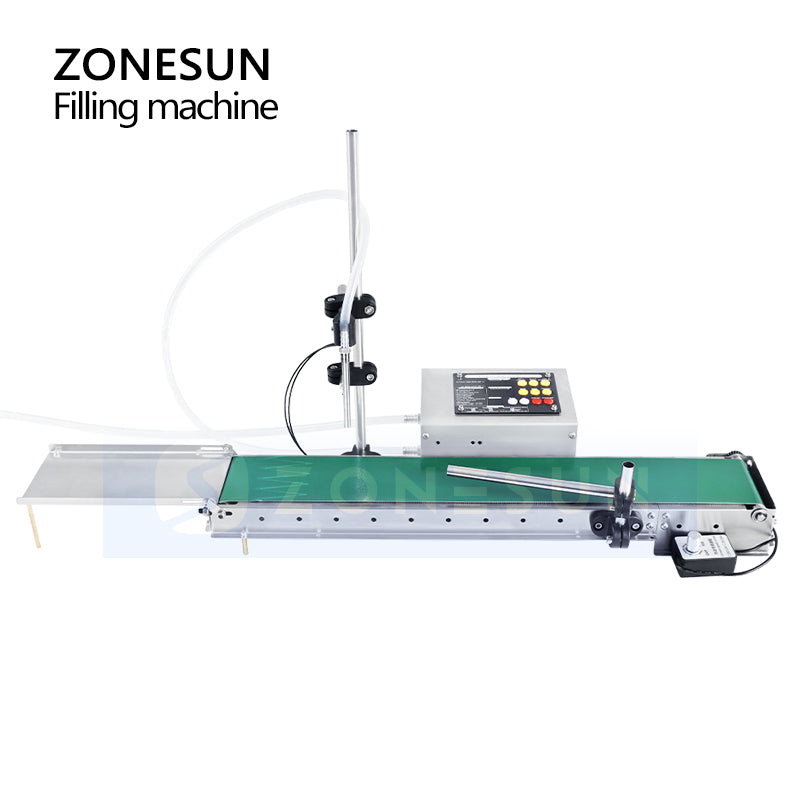

Conveyor installation and commissioning instructions

1.Insert the conveyor control cable,install copper columns and receiving tray,insert the U-shaped clip ,T-bracket and U-shaped clip ,tight the screws slowly to ensure that the bracket does not shake.

2.Install the support rod,bracket,prepare to connect the filling machine

3.Install the sensor,and inlet and outlet pipes,adjust the sensitivity of the sensor,the bottle will be filled automatically.

4.Adjust the water outlet to match the height of the bottle,comfirm the alignment of the water outlet and the bottle mouth form different angles.

5.Adjust the bottle guide rod so that the bottle just passes the sensor.

6.Start-up trial operation,after adjustment,you can start working.

Share