Collection: Perfume Production Line | Custom Packaging Solutions

ZONESUN Custom Perfume Packaging Solutions

-

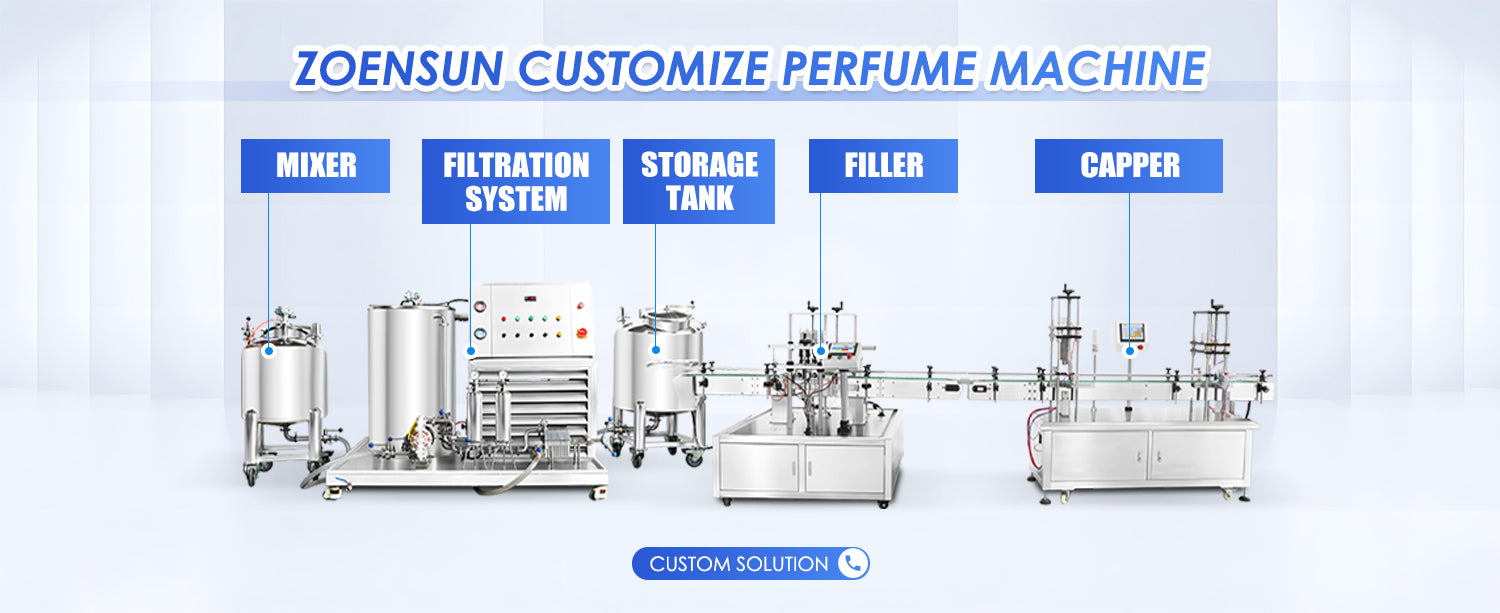

Perfume Pre-Treatment

Use purification, filtration, and a bottle washing machine to ensure clean liquid and containers before filling

-

Filling Machines

Choose from manual to fully automatic perfume filling machines. Models like ZS-YTZL500Q use pure pneumatic control, making them safer and ideal for perfume.

-

Perfume Crimping Machines

Options include manual, semi-auto, and fully automatic models. The ZS-YG08 pneumatic crimping machine is specially designed for perfume bottles.

-

Labeling Machines

Label round or flat perfume bottles with our versatile labeling equipment, including double-sided solutions for flat surfaces.

-

Box Packing Solutions

Models like ZS-MSZH70 handle cartoning, ideal for final perfume packaging.

Whether you need a single machine or a full line, ZONESUN is your trusted choice for perfume packaging solutions.

-

ZONESZONESUN ZS-MSZH80 High-Speed Horizontal Cartoning Machine for Skincare Cosmetics Perfume with Auto Box Packing and Safety Features

Regular price $33,499.00 USDRegular priceUnit price / per -

ZONESUN ZS-AFC46 Monoblock Automatic Perfume Body Mist Spray Bottle Filling Capping Machine | Servo Piston Pump | 30-40 BPM

Regular price $27,999.00 USDRegular priceUnit price / per -

ZONESUN ZS-AFC21 Automatic Perfume Packaging Monoblock

Regular price $21,399.00 USDRegular priceUnit price / per$25,000.00 USDSale price $21,399.00 USDSale -

ZONESUN Automatic Pocket Perfume Packaging Scent Fragrance Filling&Capping Machine ZS-AFC6P

Regular price $20,799.00 USDRegular priceUnit price / per -

ZONESUN Automatic Fragrance Line Perfume Packaging Machine ZS-FAL180XW

Regular price From $20,629.00 USDRegular priceUnit price / per -

Zonesun ZS-AFC9L Automatic Perfume Packaging Machine Monoblock

Regular price $17,199.00 USDRegular priceUnit price / per -

ZONESUN ZS-AFC9 Automatic Magnetic Pump Liquid Filling Perfume Bottle Capping Machine With Cap Feeder

Regular price $15,599.00 USDRegular priceUnit price / per -

Zonesun ZS-AFC17 Perfume Sample Packgaing Monoblock

Regular price $15,199.00 USDRegular priceUnit price / per -

ZONESUN ZS-AFC7D Desktop Filling and Capping Machine with Peristaltic Pump for Perfume Spray Bottle and Essential Oil Packaging

Regular price $12,999.00 USDRegular priceUnit price / per -

Zonesun ZS-AFC42 Monoblock Perfume Glass Bottle Filling Cap Pressing Crimping Machine

Regular price $11,499.00 USDRegular priceUnit price / per -

ZONESUN ZS-FAL180X Automatic Perfume Bottle Vacuum Pump Filling Crimping Machine

Regular price From $11,399.00 USDRegular priceUnit price / per -

ZONESUN ZS-AFC7C Perfume Bottle Filling Machine Scent Fragrance Packaging Monoblock

Regular price $9,499.00 USDRegular priceUnit price / per$10,000.00 USDSale price $9,499.00 USDSale -

ZONESUN ZS-TB501 Square Bottle Two Side Corner Labeling Machine for Perfume, Juice & Whisky

Regular price $9,299.00 USDRegular priceUnit price / per -

ZONESUN ZS-YG11V Automatic Perfume Bottle Crimping Machine

Regular price $11,500.00 USDRegular priceUnit price / per -

Zonesun ZS-DTYG11U Perfume Crimping Machine

Regular price $8,499.00 USDRegular priceUnit price / per -

ZONESUN ZS-VTGZ100B Automatic Perfume Gravity Overflow Filling Machine

Regular price $7,599.00 USDRegular priceUnit price / per -

ZONESUN ZS-YG09 Automatic Perfume Bottle Capping Machine

Regular price $6,299.00 USDRegular priceUnit price / per -

ZONESUN ZS-FYG01 Automatic Tabletop Pocket Perfume Filling and Cap Pressing Capping Machine

Regular price $3,879.00 USDRegular priceUnit price / per$4,500.00 USDSale price $3,879.00 USDSale -

ZONESUN ZS-AFC25 Automatic Perfume Bottle Filling and Capping Machine with Magnetic Pump and Rotary Platform for Cosmetic Packaging

Regular price $3,649.00 USDRegular priceUnit price / per -

ZONESUN ZS-DTZL500 Desktop Automatic Vacuum Perfume Liquid Filling Machine

Regular price $2,699.00 USDRegular priceUnit price / per -

ZONESUN ZS-YG12 Automatic Cap Pressing Machine Pocket Perfume Sealer

Regular price $1,699.00 USDRegular priceUnit price / per$2,000.00 USDSale price $1,699.00 USDSale -

ZONESUN ZS-PF2 Pneumatic Explosion-proof Diaphragm Pump Alcohol Perfume Liquid Filter

Regular price $1,499.00 USDRegular priceUnit price / per -

Zonesun ZS-YG08Z Perfume Bottle Crimper Perfume Crimping Machine Sprayer Sealer

Regular price $749.00 USDRegular priceUnit price / per -

ZONESUN ZS-YTZL500 Semi-automatic 4 Nozzles Vacuum Liquid Perfume Filling Machine

Regular price From $579.00 USDRegular priceUnit price / per -

ZONESUN ZS-YTZL500S Pneumatic Vacuum Single Nozzle Perfume Liquid Filling Machine

Regular price From $579.00 USDRegular priceUnit price / per -

Zonesun ZS-YTZL500Q Pneumatic Perfume Vacuum Filler

Regular price $449.00 USDRegular priceUnit price / per -

ZONESUN ZS-YG08 Pneumatic Perfume Bottle Spray Caps Capping Crimping Machine

Regular price $398.70 USDRegular priceUnit price / per -

ZONESUN ZS-GK5 13/15/18/20mm Pneumatic Perfume Capping Machine

Regular price From $305.98 USDRegular priceUnit price / per -

Zonesun ZS-TYG2 Dual-use Manual Perfume Bottle Crimper

Regular price $249.00 USDRegular priceUnit price / per -

ZONESUN ZS-YG30 13/15/18/20mm Manual Perfume Bottle Capping Machine

Regular price $200.00 USDRegular priceUnit price / per -

ZONESUN 13/15/17/20mm Manual Perfume Bottle Capping Machine

Regular price $148.50 USDRegular priceUnit price / per -

Zonesun ZS-YGP1 Manual Pneumatic Perfume Crimper

Regular price From $125.00 USDRegular priceUnit price / per -

ZONESUN Capping Chuck Customized Spray Perfume Nail Polish Cap Chuck

Regular price $63.00 USDRegular priceUnit price / per -

ZONESUN ZS-PBC1 Manual Perfume Crimper

Regular price From $39.00 USDRegular priceUnit price / per -

Zonesun 13/15/18/20mm Custom Capping Head For Perfume Capping Machine

Regular price $34.92 USDRegular priceUnit price / per -

ZONESUN Collar Ring For Perfume Bottle Capping Machine

Regular price $34.92 USDRegular priceUnit price / per

How to Choose a Perfume Production Line and Why Choose ZONESUN

When it comes to establishing a perfume manufacturing business, selecting the right production line is critical for ensuring product quality, operational efficiency, and scalability. With numerous suppliers and options available in the market, it can be challenging to know where to begin. This guide will help you navigate the key factors to consider when choosing a perfume production line and why ZONESUN is the preferred choice for many leading brands worldwide.

Key Factors to Consider When Choosing a Perfume Production Line

Production Capacity and Scalability

One of the first things to consider when selecting a perfume production line is its capacity. Whether you're starting with a small batch or aiming for large-scale production, it's important to choose a production line that matches your current and future needs. Look for a system that is flexible enough to handle both small runs and high-volume production.

Precision in Filling and Packaging

Perfume filling requires high precision to ensure that every bottle is filled consistently. A high-quality filling machine ensures accurate measurement, preventing waste and improving overall production efficiency. Machines with adjustable settings for different bottle sizes are essential for versatility.

Automation and Efficiency

Automated production lines reduce the need for manual labor, ensuring that the production process runs smoothly with minimal human error. Look for a perfume production line that integrates filling, capping, labeling, and packaging into one streamlined process. The more automated the system, the faster and more cost-effective your production will be.

Quality Control and Safety

Perfume is a delicate product, and quality control is crucial in maintaining brand reputation. Make sure your production line includes inspection systems for detecting any defects or inconsistencies in the product. Machines should also comply with industry standards for hygiene and safety.

Customization and Flexibility

Not all perfumes are the same. Different fragrances require different handling and packaging. Therefore, it's essential to choose a production line that can be customized to meet your specific needs. Look for equipment that allows you to easily change settings for various bottle shapes, sizes, and cap types.

Technical Support and After-Sales Service

When investing in a perfume production line, it's vital to have reliable technical support and after-sales service. The right supplier will not only provide equipment but also offer assistance with installation, training, and maintenance.

Why Choose ZONESUN for Your Perfume Production Line?

ZONESUN is a leading provider of high-quality, customizable production lines for a variety of industries, including the perfume sector. Here's why ZONESUN should be your go-to choice for your perfume manufacturing needs:

Comprehensive Solutions for Every Step of Production

ZONESUN offers a complete, integrated perfume production line that covers all stages of manufacturing. From mixing and blending to filling, capping, labeling, and packaging, their systems are designed to streamline every process. Their automated systems save time and reduce operational costs, allowing you to focus on growing your brand.

High-Precision Filling and Capping Machines

ZONESUN’s perfume filling machines are known for their precision. With adjustable settings for different bottle sizes and types, these machines guarantee accurate, consistent filling without any wastage. Additionally, their capping machines ensure secure and tamper-proof sealing, which is critical for perfume products.

Customizable Production Lines

ZONESUN understands that each perfume brand has unique needs. Their production lines can be tailored to meet the specific requirements of your brand, including custom designs for bottles, caps, labels, and more. Whether you produce luxury perfumes, niche fragrances, or mass-market scents, ZONESUN can create a solution that fits perfectly.

Industry-Leading Automation

ZONESUN’s production lines are fully automated, significantly reducing the need for manual labor. Their advanced systems integrate filling, labeling, capping, and packaging into a seamless process, boosting productivity and ensuring high standards of quality control. Automation ensures that your perfume production line operates efficiently and meets the demands of high-volume production.

Excellent After-Sales Service

ZONESUN is committed to providing top-notch after-sales support. They offer installation assistance, training for your operators, and ongoing maintenance to ensure that your production line stays in optimal working condition. Their technical team is always ready to assist with troubleshooting and machine optimization.

Reliable and Durable Equipment

ZONESUN’s perfume production lines are designed with durability in mind. Made with high-quality materials and engineered to withstand continuous use, their equipment provides long-term reliability, making it a sound investment for any perfume brand.

Conclusion

Choosing the right perfume production line is an essential step in ensuring the success of your fragrance manufacturing business. Consider factors like production capacity, filling precision, automation, and after-sales service when making your decision. ZONESUN offers a wide range of high-quality, customizable production solutions that will help you streamline your manufacturing process, reduce costs, and improve product quality.

If you're looking to upgrade your perfume production line or starting a new perfume manufacturing business, ZONESUN provides the expertise and equipment you need. Check out their perfume production line solutions today and take your business to the next level!